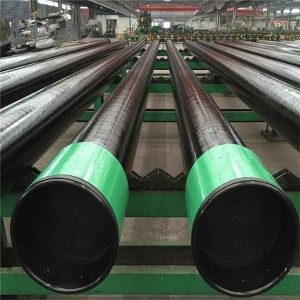

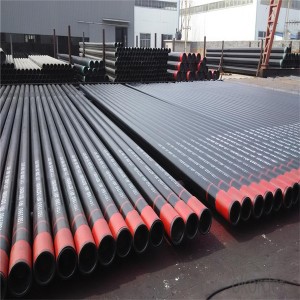

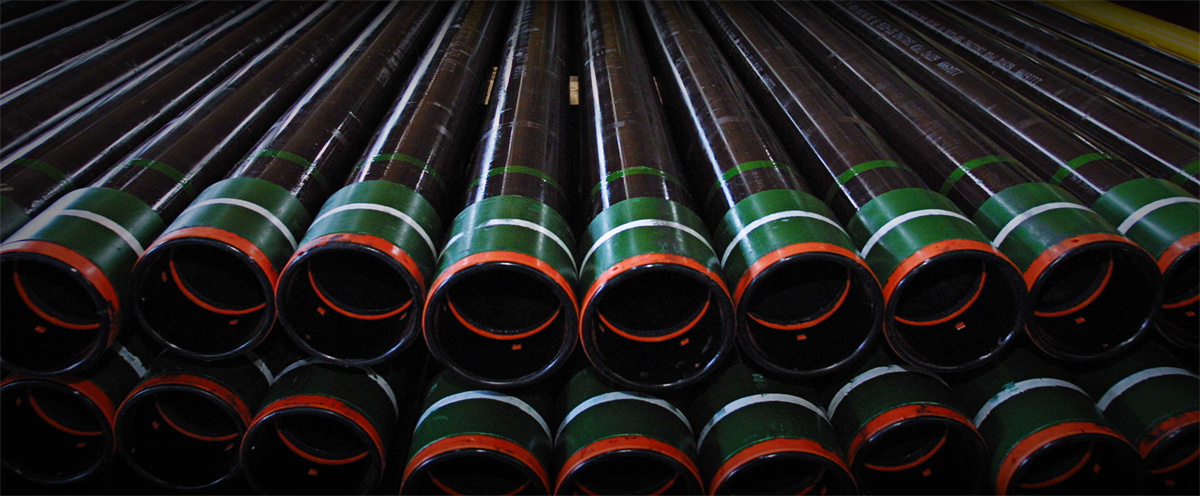

J55 K55 N80 yog 'trubkasi va korpusli po'lat quvur

Neft qobig'i - burg'ulash jarayoni va tugagandan so'ng butun neft qudug'ining normal ishlashini ta'minlash uchun neft va gaz quduqlarining devorlarini qo'llab-quvvatlash uchun ishlatiladigan po'lat quvur. Har bir quduq turli burg'ulash chuqurliklari va geologik sharoitlariga ko'ra bir necha qatlamli qobiqlardan foydalanadi. Qopqoq quduqqa tushirilgandan so'ng tsement sementlash qo'llaniladi. Neft quvurlari va burg'ulash quvurlaridan farqli o'laroq, uni qayta ishlatish mumkin emas va bir martalik iste'mol qilinadigan materialdir. Shunday qilib, korpus iste'moli barcha neft quduqlari quvurlarining 70% dan ortig'ini tashkil qiladi.

| Yorliq | D Tashqi diametri mm | Devor qalinligi t mm | C Yakuniy tugatish turi | |||||||||

| 1 | 2 | |||||||||||

| NU T&C | EI T&C | IJ | ||||||||||

| H40 | J55 | L80 | N80 1Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.9 | 2.75 | 2.9 | 2.76 | 48.26 | 3.68 | PNUI | PNUI | PNUI | PNUI | PNUI | PNUI | - |

| 1.9 | 3.65 | 3.73 | - | 48.26 | 5.08 | PU | PU | PU | PU | PU | PU | PU |

| 1.9 | 4.42 | - | - | 48.26 | 6.35 | - | - | P | - | P | P | - |

| 2 3/8 | 4 | - | - | 60.32 | 4.24 | PU | PN | PN | PN | PN | PN | - |

| 2 3/8 | 4.6 | 4.7 | - | 60.32 | 4.83 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 5.8 | 5.95 | - | 60.32 | 6.45 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 3/8 | 6.6 | - | - | 60.32 | 7.49 | - | - | P | - | P | P | - |

| 2 3/8 | 7.35 | 7.45 | - | 60.32 | 8.53 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 6.4 | 6.5 | - | 73.02 | 5.51 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 7.8 | 7.9 | - | 73.02 | 7.01 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 8.6 | 8.7 | - | 73.02 | 7.82 | - | - | PNU | PNU | PNU | PNU | PNU |

| 2 7/8 | 9.35 | 9.45 | - | 73.02 | 8.64 | - | - | PU | - | PU | PU | - |

| 2 7/8 | 10.5 | - | - | 73.02 | 9.96 | - | - | P | - | P | P | - |

| 3 1/2 | 7.7 | - | - | 88.9 | 5.49 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 9.2 | 9.3 | - | 88.9 | 6.45 | PNU | PNU | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 10.2 | - | - | 88.9 | 7.34 | PN | PN | PN | PN | PN | PN | - |

| 3 1/2 | 12.7 | 12.95 | - | 88.9 | 9.52 | - | - | PNU | PNU | PNU | PNU | PNU |

| 3 1/2 | 14.3 | - | - | 88.9 | 10.92 | - | - | P | - | P | P | - |

| 3 1/2 | 15.5 | - | - | 88.9 | 12.09 | - | - | P | - | P | P | - |

| 4 | 9.5 | - | - | 101.6 | 5.74 | PN | PN | PN | PN | PN | PN | - |

| 4 | 10.7 | 11 | - | 101.6 | 6.65 | PU | PU | PU | PU | PU | PU | - |

| 4 | 13.2 | - | - | 101.6 | 8.38 | - | - | P | - | P | P | - |

| 4 | 16.1 | - | - | 101.6 | 10.54 | - | - | P | - | P | P | - |

| 4 1/2 | 12.6 | 12.75 | - | 114.3 | 6.88 | PNU | PNU | PNU | PNU | PNU | PNU | - |

| 4 1/2 | 15.2 | - | - | 114.3 | 8.56 | - | - | P | - | P | P | - |

| Guruh | Baho | Turi | Yuklanish ostida umumiy cho'zilish % | Chiqish kuchi Mpa | Kuchlanish kuchi min MPa | Qattiqlik maks | ||

| min | maks | HRC | HBW | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| 1 | J55 | - | 0,5 | 379 | 552 | 517 | - | - |

| K55 | - | 0,5 | 379 | 552 | 655 | - | - | |

| N80 | 1 | 0,5 | 552 | 758 | 689 | - | - | |

| N80 | Q | 0,5 | 552 | 758 | 689 | - | - | |

| 2 | L80 | 1 | 0,5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | |

| L80 | 13Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | |

| C90 | 1?2 | 0,5 | 621 | 724 | 689 | 25.4 | 255 | |

| C95 | - | 0,5 | 655 | 758 | 724 | - | - | |

| T95 | 1?2 | 0,5 | 655 | 758 | 724 | 25.4 | 255 | |

| 3 | P110 | - | 0,6 | 758 | 965 | 862 | - | - |

| 4 | 125-savol | Hammasi | 0,65 | 862 | 1034 | 931 | - | - |

Quvur yuzasini vizual tekshirish

O'lchamni tekshirish

Cho'zilish kuchi, oqish kuchi va cho'zilish bo'yicha mexanik sinov

Kimyoviy tahlil

NDT testi, jumladan, magnit zarracha, ultratovush tekshiruvi, gidrostatik sinov

Charpy ta'siri testi

Yassilash testlari

Qattiqlik sinovi

Drift testi

Ip uchlarini ip o'lchagich va ulanishni tekshirish bilan tekshiring

J55 va K55 kimyoviy tarkibi va mexanik xususiyatlari bo'yicha o'xshash materialdir, ayniqsa J55 minimal kuchlanish talabiga ega va pastroq cho'zilishga ega, boshqalari texnik xususiyatlar issiqlik bilan ishlov berish usullari, NDE testi, Charpy Impact testi, gidrostatik sinov kabi bir xil.

J55/K55 minimal oqish quvvati: 379-552 Mpa;

J55 minimal kuchlanish kuchi: 517 Mpa, cho'zilish ≥ 19%;

K55 minimal kuchlanish kuchi: 655 Mpa, cho'zilish ≥ 15%.