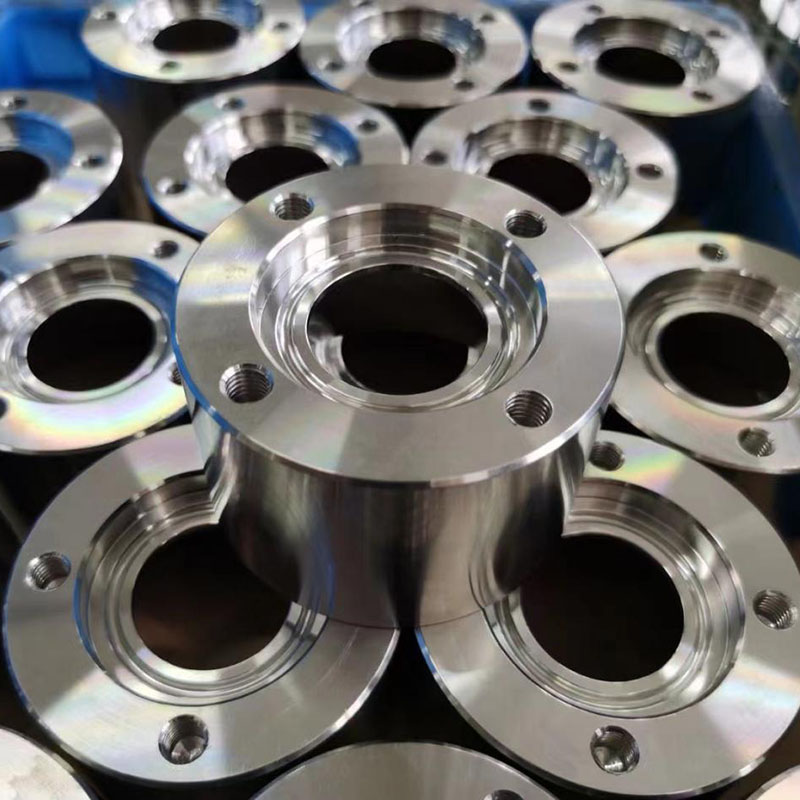

Quvur qismlari zanglamaydigan po'latdan Rf ko'r-ko'rona payvandlash bo'yin gardish

Karbonli po'lat: ASTM A105, 20 #, Q235, 16Mn; ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2; ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Zanglamaydigan po'latdan: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8.

Qotishma po'lat: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A3343P2/.

WCB (karbonli po'lat), LCB (past haroratli karbonli po'lat), LC3 (3,5% nikel po'lat), WC5 (1,25% xrom 0,5% molibden po'lat), WC9 (2,25% xrom), C5 (5% xrom 0,5% molibden), C12 (9% xrom 1% molibden), CA6NM (4 (12%) xromli po'lat), CA15 (4) (12% xrom), CF8M (316 zanglamaydigan po'lat), CF8M (316 zanglamaydigan po'lat) CF8C (347 zanglamaydigan po'lat), CF8 (304 zanglamaydigan po'lat), CF3 (304L zanglamaydigan po'lat), CF3M ( 316L zanglamaydigan po'latdan), CN7M (qotishma po'latdan), M35-1 (Monel), N7M (Hastelloy B), CW6M (Hastelloy C), CY40 (Inconel) va boshqalar.

Plastinka tekis payvandlash po'lat quvur gardish plitasi

1. Kimyo sanoati (HG) sanoat standartlariga ko'ra: integral gardish (IF), tishli gardish (Th), plastinka tekis payvandlash gardish (PL), bo'yinli payvandlash gardish (WN), bo'yinli tekis payvandlash gardish (SO), rozetka payvandlash gardishi (SW), payvandlangan payvandlash halqasining bo'sh gardish (PJ/SE), tekis payvandlash halqasi bo'sh gardish (PJ/RJ), astarli gardish qopqog'i (BL (S)), gardish qopqog'i (BL)

2. neft-kimyo (SH) sanoati standartlariga muvofiq: tishli gardish (PT), payvand choki (WN), tekis payvandlash gardish (SO), rozetkali payvandlash gardish (SW), bo'sh gardish (LJ), gardish qopqog'i (stol emas) Eslatma).

3. mashinasozlik (JB) sanoat standartlariga ko'ra: butun gardish, payvandlangan payvandlash gardish, plastinka tekis payvandlash gardish, payvandlangan payvandlash rishtasi bo'sh gardish, tekis payvandlash halqa plitasi bo'sh gardish, gardishli halqa plitasi bo'sh gardish, gardish qopqog'i.

4. milliy (GB) standartiga ko'ra: butun gardish, tishli gardish, payvand payvandlash gardishi, bo'yinli tekis payvandlash gardish, bo'yinli rozetkali payvandlash gardish, payvand payvandlash halqasi bo'yinli bo'sh o'rnatilgan gardish, plastinka tipidagi tekis payvandlash gardish, payvand payvandlash halqasi plitasi turi bo'sh o'rnatilgan gardish, tekis payvandlash halqasi plastinka turi bo'sh o'rnatilgan gardish, gardishli halqa plastinka turi bo'sh o'rnatilgan gardish, gardish qopqog'i.

Gardish suvni tejash, elektr energiyasi, elektr stantsiyalari, quvur liniyasi armaturalari, sanoat, bosimli idishlar va boshqa qozonli bosimli idishlar, neft, kimyo, kemasozlik, farmatsevtika, metallurgiya, mashinasozlik, oziq-ovqat va boshqa sohalarda keng qo'llaniladi. HVAC Elektr quvvati Bino suv ta'minoti Bosimli idishlar armaturalari, bosimli quvurlar armaturalari. Yong'in, gaz, issiq va sovuq suv, konditsioner, havo bosimi trubkasi, neft quvurlari, asboblar, gidravlik quvurlar va boshqa sanoat va fuqarolik quvurlarini qulflash muhrlari va boshqalar uchun qo'llaniladi.

Flanjni qisqartirish; zanglamaydigan po'latdan yasalgan gardish; bosimli idish gardish; tekis payvandlash gardish; bo'yinli payvandlash (WN) rozetkali payvandlash gardish (SW); tishli gardish (TH) bo'shashgan gardish

Milliy standart: GB/T9112-2010 (GB9113-1-2010~GB9123-4-2010)

Kimyo sanoati vazirligi standartlari: HG5010-52~HG5028-58, HGJ44-91~HGJ65-91, HG20592-2009 seriyali, HG20615-2009 seriyali

Mashinasozlik vazirligi standartlari: JB81-59 ~ JB86-59, JB/T79-94 ~ JB/T86-94, JB/T74-1994

Bosimli idishlar standartlari: JB1157-82 ~ JB1160-82, NB/T47020-2012 ~ NB/T47027-2012, B16.47A/B B16.39 B16.

| Element | Flanj turlari | O'lcham oralig'i(mm) | Tolerantlik(mm) |

| Flanj qalinligi C | Ikki tomonlama ishlov berishning barcha turlari | C≤18 | +20 |

| 18<C≤50 | +30 | ||

| C>50 | +40 | ||

| Flanj balandligi H | Yassi payvandlash, payvand payvandlash, bo'shashmasdan gilza, rozetkali payvandlash gardish | ≤DN250 | ±1,5 |

| DN300~DN600 | ±3,0 | ||

| Flanjning tashqi diametri D | Barcha turlari | ≤DN150 | ±1,5 |

| DN200~DN500 | ±3,0 | ||

| Plomba yuzasi balandligi F | Barcha turlari | Barcha o'lchamlar | ±0,50 |

| Bolt teshigi markazi doira diametri K | Barcha turlari | M10 ~ M24 | ±1,0 |

| M27 ~ M33 | ±1,25 | ||

| M36 ~ M52 | ±1,5 | ||

| Bolt teshigi diametri L | Barcha turlari | ≥DN10 | ±0,5 |

| Bolt teshigining markaziy doirasi va ishlov berilgan muhr yuzasining koaksiyal bardoshliligi | Barcha turlari | ≤DN65 | PH1.0 |

| DN80~DN150 | PH2.0 | ||

| DN200~DN500 | PH4.0 |